In the area of industrial processes and fluid measurement, precision is paramount. Engineers and professionals across various industries constantly seek advanced technologies to enhance accuracy and efficiency in monitoring fluid flow.

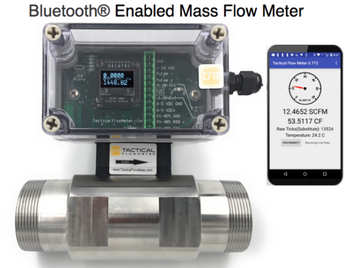

One such innovation that has gained prominence is the thermal mass flow meter, a sophisticated device that plays a pivotal role in optimizing processes.

Introduction to Thermal Flow Measurement

At the heart of modern flow measurement technology lies the thermal flow meter. This device fundamentally operates on the principle of heat transfer, utilizing the thermal properties of fluids to provide accurate measurements of mass flow rates.

How thermal mass flow meters Work

Unlike traditional flow meters that rely on mechanical principles, thermal mass flow meters harness the power of thermal conductivity. A heated sensor is placed in the flow stream, and as the fluid passes over it, the sensor measures the temperature difference between the heated sensor and the fluid.

The rate at which the heat dissipates is directly proportional to the mass flow rate, enabling precise measurement without the need for additional pressure or temperature corrections.

Advantages of thermal mass flow meters

Considering the advantages of using these flow meters, the following points explain everything well.

High Accuracy and Rangeability

One of the standout features of these flow meters is their exceptional accuracy. These devices excel in measuring low flow rates, making them perfect for applications where precision is critical. Additionally, their wide rangeability ensures reliable performance across varying flow conditions, allowing for versatility in industrial setups.

Minimal Pressure Drop and Energy Consumption

Traditional flow meters often introduce pressure drop issues, impacting the overall efficiency of a system. Thermal flow meters, on the other hand, have minimal impact on the fluid dynamics, ensuring that the pressure drop is negligible.

This characteristic not only preserves the integrity of the system but also contributes to energy savings, a crucial factor in today's eco-conscious industrial landscape.

Versatility Across Industries

From oil and gas to chemical processing, these flow meters find applications in diverse industries. Their adaptability to different fluids and the ability to easily withstand harsh environmental conditions make them a preferred choice for engineers seeking reliable and robust flow measurement solutions.

Considerations for Implementation

Precision in installation and regular calibration is paramount for maximizing the benefits of these flow meters, ensuring accuracy and reliability.

Installation and Calibration

Proper installation and calibration are pivotal to unlocking the full potential of thermal flow meters. Ensuring that the device is correctly placed in the flow stream and regularly calibrated is essential for maintaining accuracy and reliability.